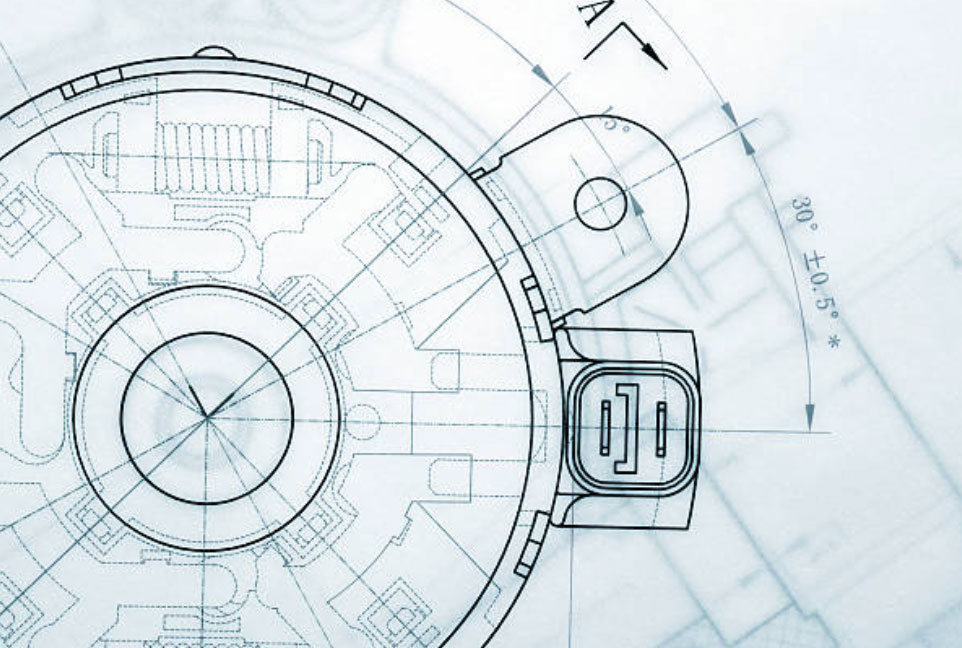

Surface Treatment

Discuss the technical solution with our engineers! Surface treatments on cartridge & insert distributors can lead to improved extrusion processes especially when extruding critical polymers such as PEEK or rubber. Over the years, we developed with specialized partner companies coating & cleaning processes for an easier handling & cleaning.

Cleaning & blasting technology

Plastic blasting technology – Contract blasting – Cleaning

Distribution of blasting systems

Modification of blasting systems for screw cleaning

Surface coatings

Surface compaction – peening

Micropeening

Special coatings based on TiC & TiN

The surfaces of the compound distributors & extrusion tools play a major role in product quality & can be critical, especially with polymers that are difficult to process, such as PEEK. Over the years, we have worked with specialized partner companies to develop ways of optimizing extrusion and cleaning behaviour. In many cases, surface finishing can have a positive effect on wall roughness, resulting in significantly lower pressure peaks and therefore better surfaces. Plastic blasting technology enables a very gentle cleaning option not only for cross extrusion heads, but also for screws, which does not attack the surfaces in the long term. Special coatings can reduce corrosion phenomena and pressure peaks in special cases. Our team will be happy to advise you!