Bypass valves

Bypass valves or pressure relief valves are metallic sealing valve systems that are specially designed for the diversion of a polymer melt flow.

These valves are supplied as a separate unit and can be installed on the main extruder side as well as on the co-extruder side of the crosshead.

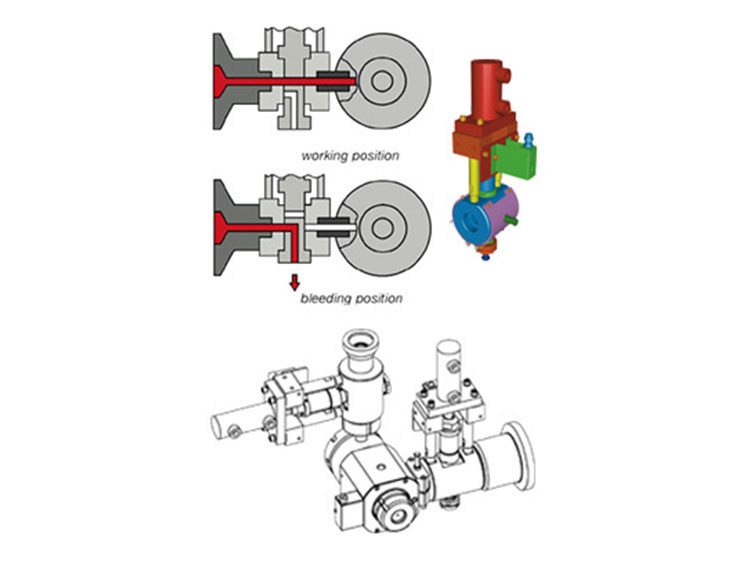

Function

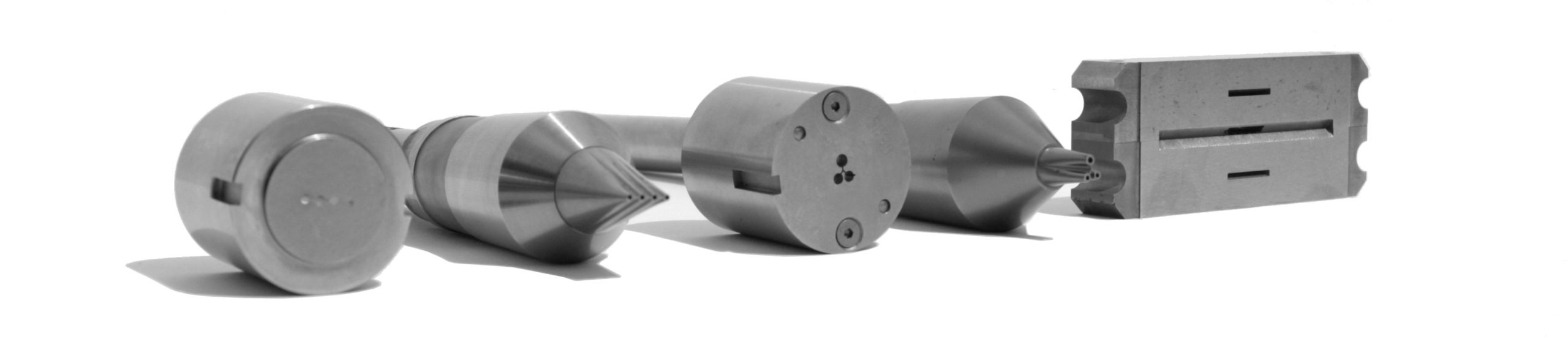

Bypass valves with rotating pistons

Bypass valves with axially displaced piston

Flow channel diameter

(8) / 10 / 15 / 20 / 25 / 30 / (50)mm

(0.314″) / 0.393″ / 0.590″ / 0.787″/ 0.984″ / 1.181″ / (1.196″)

Drive

Manually actuated bypass valves with rotating pistons

Hydraulically operated bypass valves with axially displaced piston

Pneumatic drives for upgrade

Bypass valves or pressure relief valves are metallic sealing valve systems specially designed for the diversion of a polymer melt flow. These valves come as a separate unit and can be installed on the main extruder side as well as on the co-extruder side of the crosshead. In case of maintenance works, conductor breaks or simply a tool change the melt flow can be easily diverted in order to facilitate the handling of the crosshead and to avoid a stop of the extruder. A wide range of working diameters and casing sizes are manufactured according to your need. The UNITEK bypass systems are available with manual, hydraulic or pneumatic actuation. In case of a hydraulic or pneumatic system, it is possible to fully integrate it into a new or existing line control – ideal for the retrofit of your extrusion line.